Coalescing

Filter • Compressed Air Filters

Natural Gas Filters • Air Oil Separation

We manufacture

coalescing filters for any industrial application.

Allied

Groups' coalescing filter is designed for all compressed air, natural

gas, refrigeration, CNG/NGV (compressed natural gas/natural gas

vehicles) and Air/Oil filter applications. Our coalescing filter can be designed with oil mist removal efficiencies up to 99.9999%

with working pressures to over 5000 PSI.

Allied

Groups' coalescing filter is designed for all compressed air, natural

gas, refrigeration, CNG/NGV (compressed natural gas/natural gas

vehicles) and Air/Oil filter applications. Our coalescing filter can be designed with oil mist removal efficiencies up to 99.9999%

with working pressures to over 5000 PSI.

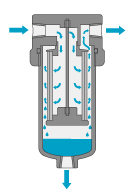

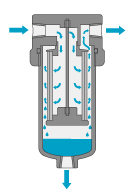

Coalescing

is the separation of liquid aerosols and droplets from a gas.

Using a coalescing filter element installed in a housing with

three ports the wet gas sample passes though element

inside to outside. The inner capture layer is a high efficiency

coalescing layer and the outer is a coarser drainage layer.

The fine fibres of the inner layer capture the fine liquid aerosols

and droplets and they run together along the fibres to form large

drops within the depth of the element. These large drops are

then forced to the outside of the filter element and then

drain to the bowl of the housing by gravity. Coalescing filter elements will also remove particulates at the same efficiency as particulate type elements of the same grade.

Our

capabilities range from filters as small as 0.18” inside diameter

to over 22” outside diameter. We have custom designed our

coalescing filters for many applications and have extensive tooling

to satisfy applications that require standard filter sizes. We can

cross reference filters made by Parker, Balston, Bendix, Microbon

and many other manufacturers.

Our

natural gas filters are manufactured for all car, truck and bus

applications. We design our filters to protect vital components

from oil mist build-up and fouling. We have been supplying coalescing

filters for alternative fuel applications for the last 10 years.

Our filters have been tried and true for most any demanding compressed

gas filter application.

Our

coalescing filters are manufactured for all compressed air applications

and in-line filter applications, to remove oil mist from the compressors

that introduce oil vapor into the gas stream.

Allied Group's coalescing filters are

constructed of three layers. The inner and outer layer act as built-in

pre-filters, depending on an outside to inside flow or inside to

outside flow. These are also the drain and support layers. The middle

layer - "binder free" borosilicate microglass - is the

coalescing portion of the filter. Pre-filtering removes dirt particles

prior to coalescing thereby increasing filter life.

In

most applications, our built-in pre-filter will eliminate the need

for a separate pre-filter.

Inner

and outer layers are made of rayon fibers, impregnated with phenolic

resin (see Figure 1). Situated between these layers is the coalescing

layer (borosilicate microglass). Efficiencies range from 93% to

99.9999% at the 0.3 micron range. The pre-filter can be constructed

with microns from 1 to 75. We will custom design for new applications

or cross reference competitive filters for existing applications.

Inner

and outer layers are made of rayon fibers, impregnated with phenolic

resin (see Figure 1). Situated between these layers is the coalescing

layer (borosilicate microglass). Efficiencies range from 93% to

99.9999% at the 0.3 micron range. The pre-filter can be constructed

with microns from 1 to 75. We will custom design for new applications

or cross reference competitive filters for existing applications.

Coalescing

Filters are used in many applications, including, but not limited

to:

Natural Gas Vehicle Filtration (NGV)

Compressed Air Filtration

Compressed Natural Gas Filtration (CNG Filtration)

Mist Elimination

Aerosol Removal

Air Oil Separation

Refrigeration

Allied

Groups' coalescing filter is designed for all compressed air, natural

gas, refrigeration, CNG/NGV (compressed natural gas/natural gas

vehicles) and Air/Oil filter applications. Our coalescing filter can be designed with oil mist removal efficiencies up to 99.9999%

with working pressures to over 5000 PSI.

Allied

Groups' coalescing filter is designed for all compressed air, natural

gas, refrigeration, CNG/NGV (compressed natural gas/natural gas

vehicles) and Air/Oil filter applications. Our coalescing filter can be designed with oil mist removal efficiencies up to 99.9999%

with working pressures to over 5000 PSI. Inner

and outer layers are made of rayon fibers, impregnated with phenolic

resin (see Figure 1). Situated between these layers is the coalescing

layer (borosilicate microglass). Efficiencies range from 93% to

99.9999% at the 0.3 micron range. The pre-filter can be constructed

with microns from 1 to 75. We will custom design for new applications

or cross reference competitive filters for existing applications.

Inner

and outer layers are made of rayon fibers, impregnated with phenolic

resin (see Figure 1). Situated between these layers is the coalescing

layer (borosilicate microglass). Efficiencies range from 93% to

99.9999% at the 0.3 micron range. The pre-filter can be constructed

with microns from 1 to 75. We will custom design for new applications

or cross reference competitive filters for existing applications.